In tinned copper

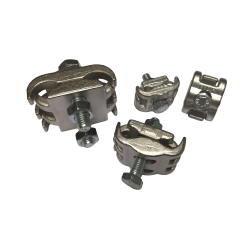

Tubular compression lugs are used to connect electrical cables, for example on metallic frames or equipotential bonding bars, and typically on the connection terminals of electrical equipment. The mounting is made by crimping and requires specific tooling composed of a crimping press and associated set of dies. The lugs are made of tinned copper by electrolysis in order to be able to be connected on, for example, aluminium frame.

MALTEP proposes a range of tubular compression lugs made of tinned copper according to the NF C20-130 manufacturing standards. Our standard range allows to equip cables of cross sections starting from 6 to 400mm². MALTEP can propose you other diameters of terminal holes or lugs meeting other manufacturing standards on request.

| Tubular Lugs NFC20-130 |

Dies as per crimping tool | ||||

| K22 | BLP55 | MP13026 | BP13026 | XPU210-5(*) | |

| COT6 | – | D55HFCU6/35L9/9 | C130HFCU6L9 | – | |

| COT10 | – | D55HFCU10/50L9/5 | C130HFCU10L9 | – | |

| COT16 | OUTIL-K22-NF2216 | D55HFCU16/70L9/5 | C130HFCU16L9 | – | |

| COT25 | OUTIL-K22-NF2225 | D55HFCU25/95L9/5 | C130HFCU25L9 | U130HFCU25L9 | |

| COT35 | OUTIL-K22-NF2235 | D55HFCU6/35L9/9 | C130HFCU35L12 | U130HFCU35L5x2 | |

| COT50 | OUTIL-K22-NF2250 | D55HFCU10/50L9/5 | C130HFCU50L12 | U130HFCU50L5x2 | |

| COT70 | OUTIL-K22-NF2270 | D55HFCU16/70L9/5 | C130HFCU70L12 | U130HFCU70L5x2 | |

| COT95 | OUTIL-K22-NF2295 | D55HFCU25/95L9/5 | C130HFCU95L12 | U130HFCU95L5x2 | |

| COT120 | OUTIL-K22-NF22120 | D55HFCU4/120L9/5 | C130HFCU120L12 | U130HFCU120L5x2 | |

| COT150 | OUTIL-K22-NF22150 | D55HFCU150L5 | C130HFCU150L12 | U210HFCU150L5x2 | |

| COT185 | OUTIL-K22-NF22185 | D55HFCU185L5 | C130HFCU185L12 | U210HFCU185L5x2 | |

| COT240 | OUTIL-K22-NF22240 | D55HFCU240L5 | C130HFCU240L12 | U210HFCU240L5x3 | |

| COT300 | – | – | C130HFCU300L12 | U210HFCU300L5x3 | |

| COT400 | – | – | – | U210HFCU400L5x3 | |

| * Adapter U210-U130 is required with dies of type U130 | |||||

|

|

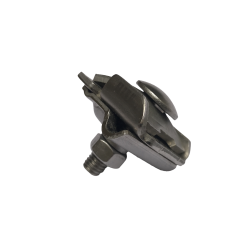

Discover our crimping tool range |

Data sheet

Download

VINCI ENERGIES and SENELEC launched work on the second phase, called Pôle 2026, of the Senegalese electricity network development project

Protect your welding equipment from handling and storage incidents and make it easy to store.